As a civil engineering pupil, I had the chance to discover numerous branches of engineering, together with electrical. Throughout this journey, I used to be launched to printed circuit board (PCB) design, and I used to be fascinated by the method of making circuits and understanding how every part works collectively to kind a useful design.

I shortly realized that selecting the finest PCB design software program is essential to making sure environment friendly, dependable, and high-quality designs. The precise software program streamlines the design course of, gives strong instruments for routing, simulating, and validating circuits, and helps handle complexity whereas guaranteeing the ultimate product meets all technical necessities.

Quick-forward to right this moment—I’ve examined a variety of PCB design software program instruments to guage their efficiency, usability, and options. With so many choices obtainable, it was vital for me to dive deep and assess how every instrument handles real-world tasks.

By mixing my private testing expertise with precious suggestions from G2 customers, I’ve compiled an inventory of the 7 finest PCB design software program that will help you discover the very best match on your personal tasks.

7 finest PCB design software program: My picks for 2025

- Altium Designer for its superior design instruments and intensive part library ($355/mo)

- Altium 365 for its PCB structure editor and 3D visualization capabilities (Price depends upon connectors chosen)

- PADS Skilled for its capability to deal with complicated PCB layouts and superior routing options ($286.92/mo)

- Allegro PCB Designer for its capability to handle high-density PCB designs and error correction methods (Accessible on request)

- Autodesk Fusion for its built-in method to mechanical and electrical design, together with 3D design capabilities ($85/mo)

- Altium CircuitMaker for being a community-driven, open-source PCB design instrument (Free)

- Autodesk EAGLE for its intuitive consumer interface and schematic seize capabilities (Accessible on request)

* These PCB design software program are top-rated of their class, in line with G2 Grid Studies.

My high 7 finest PCB design software program suggestions for 2025

PCB design software program is a robust instrument used to create and optimize printed circuit board layouts. It helps engineers design the digital circuits that kind the spine of recent units.

As I explored the very best PCB design software program, I discovered they provide greater than fundamental structure capabilities. They supply superior options comparable to real-time collaboration, 3D visualization, and error-checking.

Testing numerous instruments on small tasks allowed me to establish options that improved the design course of whereas additionally serving to me relive my engineering days. On this article, I’ll spotlight what made these instruments stand out and the way they helped me overcome frequent design challenges.

How did I discover and consider the very best PCB design software program?

I extensively examined the very best PCB design software program to create, optimize, and handle PCB layouts. To deepen my understanding, I additionally linked with electrical engineers to find out about their wants and challenges when designing PCBs and utilizing these instruments. Moreover, I used AI to research G2 consumer suggestions and G2’s Grid Studies to achieve additional insights into every instrument’s options, ease of use, and total worth. By combining hands-on testing with professional insights and consumer opinions, I’ve curated an inventory of the very best PCB design software program that will help you select the best instrument on your design wants.

What I search for in PCB design software program

When evaluating PCB design instruments, I think about options that streamline the design course of, improve effectivity, and make sure the creation of high-quality, dependable circuits:

- Superior routing capabilities are important for complicated designs. The software program ought to enable for fast computerized routing of traces, particularly in multi-layer PCBs, but it surely should additionally let me make guide changes to fine-tune the sign paths. It ought to deal with layer transitions easily, routing indicators by way of inside layers utilizing vias. By way of stitching is vital for creating a fair floor or energy aircraft, which helps scale back noise and enhance sign high quality. The software program must also assist impedance-controlled routing to make sure the traces meet particular impedance necessities, which is essential for high-speed circuits. Lastly, it ought to let me modify hint width and clearance to fulfill manufacturing and electrical requirements.

- Design rule checks (DRC) are important for me to establish potential design errors earlier than transferring into manufacturing. The software program I exploit should present customizable DRC settings that assist examine for violations of design constraints like hint width, pad sizes, through dimensions, and clearance between traces, pads, and vias. I would like to have the ability to create guidelines primarily based on the fabrication capabilities of the PCB producer, comparable to minimal hint width and most present carrying capability. The software program ought to routinely flag errors like hint overlap, unconnected nets, or part misplacement and generate an easy-to-read report for additional evaluation so I can handle points early.

- Electrical rule checks (ERC) are simply as vital to make sure the circuit features accurately. ERC helps me catch points associated to {the electrical} connectivity of elements and indicators, comparable to unconnected nets, energy/floor shorts, and incorrect part values. The software program should be certain that all elements are linked as proven within the schematic and that no unintended electrical paths are created. For instance, it ought to examine for floating pins on built-in circuits (IC), mismatched energy rails, and incorrect web assignments. In high-speed designs, ERC must also be able to figuring out potential sign integrity points, comparable to unbalanced differential pairs and floor bounce, which might have an effect on circuit efficiency.

- Assist for multi-layer PCB designs, particularly for high-density or high-performance functions, multi-layer PCBs are sometimes required. The software program I exploit ought to enable for the seamless creation of four-layer, six-layer, or much more complicated designs. It’s vital for me to have the ability to outline layer stacks, with inside layers used for routing and outer layers for part placement. The instrument should additionally assist energy and floor planes to make sure electrical stability by minimizing electromagnetic interference (EMI). Moreover, the power to deal with blind vias (vias that don’t undergo all layers) and buried vias (vias that solely join inside layers) is essential for holding the design compact. The software program must also routinely optimize the routing between layers and effectively handle each sign integrity and energy integrity in multi-layer configurations, which is vital for high-quality, dependable designs.

- Sign integrity evaluation is crucial for me to make sure that high-speed indicators are transmitted with out degradation. The software program I exploit should come geared up with SI simulation instruments that analyze elements like hint impedance, sign reflection, crosstalk, and electromagnetic interference (EMI). These instruments assist me perceive how indicators behave on the PCB and guarantee they continue to be dependable, particularly in complicated designs. Options like sign path evaluation and eye diagrams are essential as a result of they permit me to visualise the standard of sign transmission and examine for any points that might have an effect on efficiency. This offers me confidence that the design will meet the required sign integrity requirements.

- As somebody new to instrument testing, having a complete part library is a large time-saver for me. The software program ought to include a variety of frequent elements, every together with correct footprints, symbols, and 3D fashions, which makes it a lot simpler to get began while not having to manually create every half. When working with customized elements, the software program should enable me to simply create and modify footprints and symbols, which helps me outline vital parameters like pad measurement, gap diameter, and pitch. This ensures that every one elements match accurately on the PCB.

- 3D visualization is invaluable for verifying the bodily structure of the PCB. This function lets me view the PCB in three dimensions to establish potential mechanical conflicts, comparable to elements that will collide with the enclosure or different components of the design. It helps confirm part orientation and clearances between elements and traces. Moreover, the power to simulate meeting in 3D can be certain that all elements match as supposed earlier than manufacturing, stopping expensive redesigns. The 3D mannequin additionally aids in confirming the mechanical integrity of the board, guaranteeing there may be ample stiffness and assist for elements that will expertise bodily stress throughout operation.

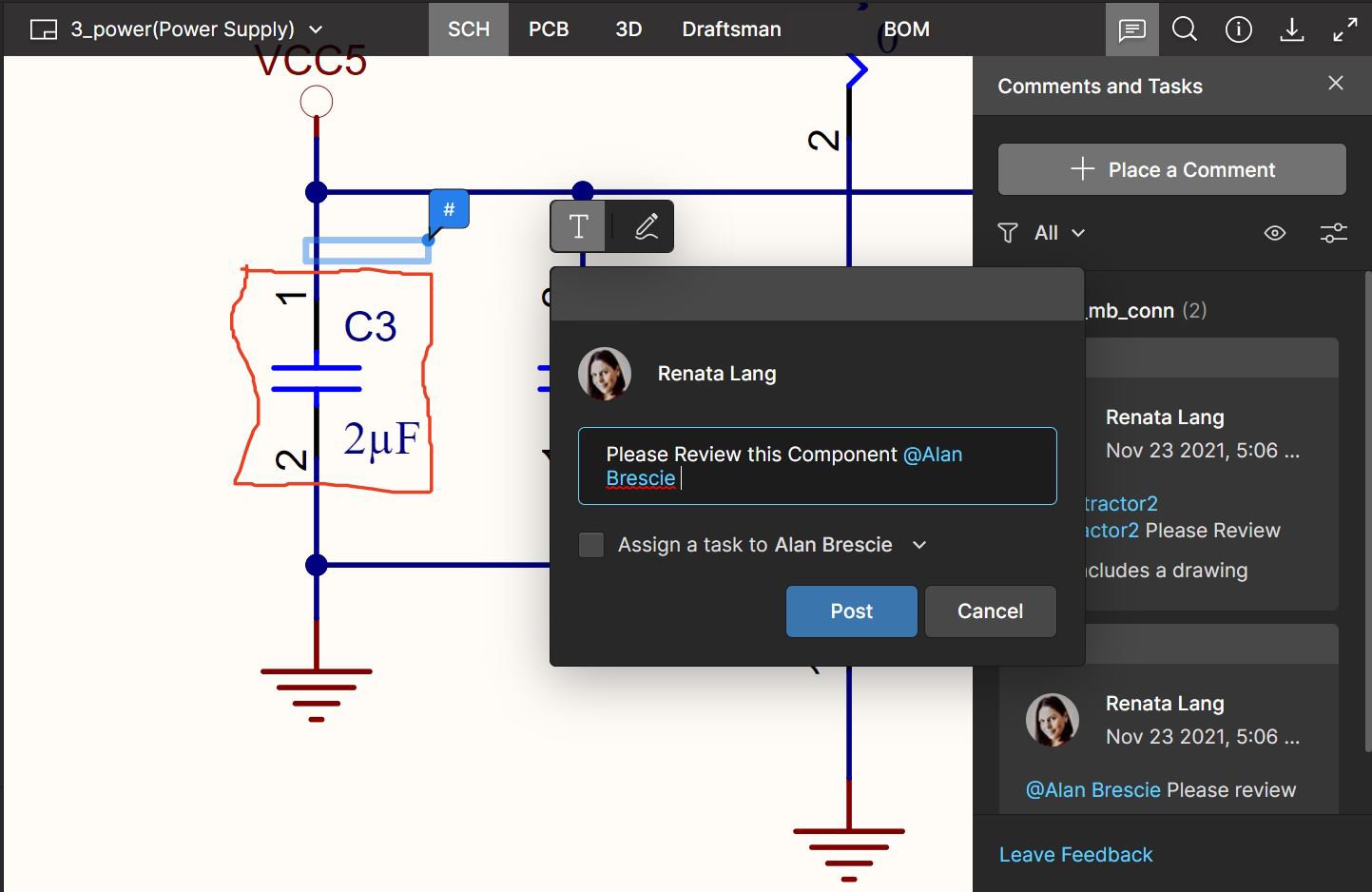

- Collaboration instruments are important when working in a group atmosphere. I search for software program that helps cloud-based design sharing, permitting for seamless real-time collaboration amongst group members, no matter location. The flexibility to implement model management throughout the design instrument is significant for monitoring modifications and stopping unintentional overwrites of vital information. I favor instruments that enable feedback and annotations throughout the design information in order that the whole group can focus on and resolve points instantly throughout the software program. This function is especially helpful for groups that work in iterative design cycles or when integrating suggestions from numerous stakeholders. Design historical past monitoring ensures that I can revert to earlier variations of the design if vital.

The checklist beneath incorporates real consumer opinions from our greatest PCB design software program class web page. To qualify for inclusion within the class, a product should:

- Modify PCB layouts and PCB circuitry

- Embrace a elements library so customers can simply implement high-quality PCB footprints

- Present schematic enhancing instruments for modification {of electrical} properties and different attributes of elements, wires, nets, and pins.

This information has been pulled from G2 in 2025. Some opinions have been edited for readability.

1. Altium Designer

Altium Designer affords a unified platform that integrates completely different design instruments, together with schematic seize, structure routing, documentation, and simulation, into one atmosphere. What I recognize most is the power to seamlessly transfer between these phases. For instance, as soon as I create the schematic diagram, I can simply transition to the layout-routing section, adjusting the design whereas visualizing the ultimate product. This clean workflow saves me time and helps me hold every little thing organized while not having to change between a number of instruments or fear about integration points.

A function that basically impressed me is design for manufacturing (DFM). This ensures that designs aren’t solely useful but additionally simple to supply. The DFM instruments assist establish potential points early within the course of, lowering errors and saving time in the course of the manufacturing section. It’s reassuring to know that my design is optimized for manufacturing earlier than transferring on to precise fabrication.

With the 3D flex-rigid design, I used to be in a position to visualize how the completely different layers of a PCB interacted, together with each versatile and inflexible components. This was particularly helpful when testing extra complicated, multi-layered designs. I can see how seeing how every part interacts in 3D may give producers higher perception and assist them make extra knowledgeable choices whereas routing the structure.

Its intensive part library affords an enormous collection of components, elements, and templates, which allowed me to shortly discover what I wanted. This function reduces the necessity to manually design elements from scratch, and I used to be in a position to make use of pre-validated components that helped reduce errors. The big variety made the method quicker and extra dependable, which is all the time a plus.

The largest problem I confronted was the system necessities. Altium Designer requires plenty of reminiscence and processing energy. On high-end machines, the software program runs easily, however on much less highly effective computer systems, I skilled noticeable slowdowns, particularly when coping with bigger, extra complicated tasks.

Attempting to run a number of instruments without delay typically resulted in lag, which made the expertise irritating. For customers with much less highly effective methods, this might actually impression workflow and productiveness.

One other ache level for me was including footprints to units. Whereas Altium affords a big collection of footprints, the method felt a bit cumbersome. Discovering the best footprint requires navigating by way of a number of libraries, and there isn’t a easy option to view all obtainable choices for a part in a single place.

Linking the footprint to the schematic image additionally felt disjointed, because it wasn’t all the time clear if the right one was chosen. There wasn’t a simple option to confirm the accuracy of the footprint after it was added, which led to some additional steps to make sure every little thing was accurately aligned. I discovered this to be time-consuming and a bit irritating, particularly when attempting to work effectively.

The studying curve can be one thing to remember. Altium Designer is full of options, which is nice for skilled customers however may be overwhelming for rookies like me. The interface is filled with choices, and it took me a major period of time to familiarize myself with all of the instruments.

What I like about Altium Designer:

- The unified platform of Altium Designer made it simple for me to maneuver seamlessly between design phases, from schematic seize to structure routing. This saved me time and stored every little thing organized while not having to change between completely different instruments.

- The DFM function actually impressed me by serving to optimize designs for manufacturing. It allowed me to establish potential points early, scale back errors, and guarantee my design was prepared for fabrication.

What G2 customers like about Altium Designer:

“Altium Designer gives every little thing wanted for design and structure in a single instrument, eliminating the necessity for added purchases. It integrates seamlessly with large-part databases, providing pricing, availability, and environment friendly manufacturing BOM era. The built-in SPICE instrument helps analog simulation, and its structure options embrace matched size routing, managed impedance, differential pairs, and each guided guide and auto-routing, which save vital time as soon as mastered. The mixing of 3D mechanical fashions into designs and outputs for mechanical use is extremely helpful. Total, Altium Designer is the very best digital design instrument I’ve ever used.”

– Altium Designer Assessment, Tim T.

What I dislike about Altium Designer:

- The system necessities for Altium Designer had been difficult for me, because it requires plenty of reminiscence and processing energy. On much less highly effective computer systems, I skilled slowdowns and lag, which considerably impacted my workflow, particularly with bigger, extra complicated tasks.

- Including footprints to units was a irritating course of for me. Navigating by way of a number of libraries and linking the footprint to the schematic image wasn’t simple, and I discovered myself spending additional time verifying every little thing was right, which slowed me down.

What G2 customers dislike about Altium Designer:

“One space for enchancment is including extra options to the “Producer Half Search.” Moreover, navigating the software program with no mouse may be difficult, particularly when utilizing a laptop computer. Proper-clicking and dragging on a trackpad may be irritating, although that’s partly because of the laptop computer design. One other suggestion pertains to defining board measurement; for example, once I wanted a board that was precisely 50mm x 50mm, it was onerous to attract exact traces. I ended up setting the grid measurement to 1mm and estimating the scale. It will be useful to have a function that shows the size of line drawings or the scale of the shapes being created.”

– Altium Designer Assessment, Trevor M.

2. Altium 365

One of many standout options of Altium 365 is its real-time collaboration capabilities. It helped me join with circuit groups on the identical designs concurrently. Whether or not I used to be reviewing schematics or making PCB structure changes, it ensured everybody was on the identical web page. The platform’s model management system ensured that each change is tracked, which allowed me to view revision histories or roll again to earlier variations with ease.

It has extremely environment friendly mission administration instruments which have made dealing with complicated designs a lot simpler, particularly once I’m engaged on intricate designs. I discovered the method of making and modifying elements to be each intuitive and highly effective, permitting for detailed work with out feeling overwhelming. I can see how this flexibility could be an enormous asset for groups, enabling them to handle large-scale tasks with ease.

I’ve additionally actually loved working with the PCB structure editor. It’s extremely customizable, which permits me to make changes to designs shortly and seamlessly. I actually appreciated the power to effortlessly transition between schematic and PCB. It saved me plenty of time, as I might shortly modify and export designs. For groups that have to combine these modifications into their bigger platform-based tasks, this function would make the whole course of rather more environment friendly, notably when fast changes are required.

The 3D visualization function was one other space the place Altium 365 impressed me. I used to be in a position to visualize how elements match on the board with ease, particularly in tight areas. The software program’s assist for .step 3D our bodies made it simple to see how every little thing would match collectively. What stood out was the 3D rendering velocity – even when working with complicated elements, they rendered shortly with none noticeable lag. I discovered the “snap factors” function notably helpful, because it helped me place even probably the most awkward 3D our bodies with nice precision.

Lastly, the draftsman instrument has been an absolute spotlight. Producing high-quality meeting drawings was a breeze with just some clicks. This instrument allowed me to create detailed and visually interesting drawings, which I might think about could be very useful for manufacturing groups that want clear documentation for meeting.

Nevertheless, regardless of these constructive experiences, there are a number of areas the place I feel Altium 365 might enhance. One of many challenges I confronted was with organising PCB routing guidelines. It required a little bit of programming data, which could not be beginner-friendly. Whereas I ultimately grew to become proficient, I might see how somebody new to this kind of design software program would possibly discover this function a bit difficult. A extra user-friendly interface for setting these guidelines would definitely make the method smoother for rookies.

One other problem I encountered was with the design rule system. Some customized queries didn’t work as anticipated, notably when attempting to arrange guidelines to disregard interfering elements. For instance, I created a “part clearance” rule with particular settings for vertical and horizontal clearance, however the rule didn’t constantly ignore collisions. Regardless of prioritizing the rule accurately, it didn’t work on some events, which was irritating.

I additionally bumped into a problem with observe size calculation. There have been occasions when Altium appeared to disregard small segments of the observe on sure layers, which could possibly be problematic when attempting to exactly match observe lengths, particularly for impedance-controlled designs. This led to inaccuracies within the structure, requiring me to manually modify and double-check sure areas.

On a number of events, Altium 365 additionally skilled reminiscence violation errors, which had been a bit regarding given the software program’s complexity. Whereas it labored properly for many of my tasks, bigger and extra complicated designs brought about the instrument to decelerate, particularly when working over a community. This resulted in longer load occasions and delays in accessing information, which could possibly be irritating throughout tight mission timelines.

Lastly, the Invoice of Supplies (BOM) function took longer than anticipated to generate. Moreover, it wanted to be up to date each time I made modifications to the schematic, which added delays to the workflow, particularly when working with frequent design revisions.

What I like about Altium 365:

- Altium 365’s mission and library administration instruments made dealing with complicated designs a lot simpler for me. Their intuitive and highly effective options allowed detailed work with out feeling overwhelming, which might be precious for groups managing large-scale tasks.

- The 3D visualization function impressed me, because it allowed me to shortly see how elements match on the board, even in tight areas. Quick rendering and exact placement utilizing the “snap factors” function drastically enhanced the design course of.

What G2 customers like about Altium 365:

“What I really like most about Altium 365 is how effortlessly it allows cloud-based collaboration, making it very best for real-time PCB design tasks, particularly for worldwide groups. Its seamless integration with Altium Designer and the power to entry designs from wherever makes it my go-to instrument, one I exploit nearly day by day. For these utilizing model management instruments like Git, the centralized library administration and reusable design choices considerably velocity up growth. The intuitive interface turns into simple to navigate with some preliminary exploration, making it sensible for practically any PCB mission. Plus, the rising neighborhood assist is invaluable.”

– Altium 365 Assessment, Angel O.

What I dislike about Altium 365:

- The setup of PCB routing guidelines required some programming data, which wasn’t very beginner-friendly, making the training curve steeper for brand new customers. A extra user-friendly interface for these guidelines would enhance the expertise for these simply beginning out.

- I encountered points with the design rule system. Customized queries typically didn’t work as anticipated, particularly with part clearance guidelines, inflicting frustration when the foundations didn’t constantly forestall collisions.

What G2 customers dislike about Altium 365:

“The software program may be gradual to start out and entry information, particularly over a community. Some default settings, just like the connection matrix, generate pointless warnings that make it more durable to establish actual points. The Invoice of Supplies function takes time to generate and requires updates when modifications are made to the schematic. Moreover, the software program slows down with bigger designs, and whereas it integrates properly with third-party elements, occasional points with mismatched footprints or image requirements can come up.”

– Altium 365 Assessment, Hemant A.

3. PADS Skilled

One of many greatest strengths I seen about PAD Skilled is its capability to deal with complicated PCB layouts. This function was notably helpful once I created intricate designs requiring exact management.

The interactive options, particularly the auto-routing choices, actually stood out to me. It sped up the structure course of considerably, and I might visually observe the routing because it progressed, which made the whole course of smoother and extra environment friendly.

One other standout facet is the intensive documentation. As somebody new to the instrument, I relied closely on the documentation, and it did not disappoint. It coated every little thing from fundamental performance to extra superior choices, serving to me shortly perceive options that might have in any other case been difficult to determine.

I additionally appreciated the schematic half view, which helps you to rotate elements at completely different angles. This was a surprisingly useful function, making it simpler to visualise and work with steadily used elements, particularly those who want particular orientations.

One of the spectacular integrations I got here throughout was the hyperlink to HyperLynx for sign integrity or energy Integrity simulations. I might effortlessly carry out detailed simulations, and the seamless integration actually enhanced the instrument’s capabilities. It felt like having a powerhouse of research at my fingertips.

The versatile design constraint system allowed me to outline particular design guidelines simply. This added precision to designs and ensured compliance with manufacturing necessities. Nevertheless, this function might shine much more if paired with improved usability for template creation.

I discovered the preliminary setup a bit overwhelming. The instrument affords plenty of options, however getting it up and operating wasn’t so simple as I had hoped. The method felt unnecessarily complicated and may gain advantage from a extra streamlined method.

Whereas the outdated GUI works, the interface feels outdated in comparison with trendy PCB design instruments. It’s useful, however the lack of intuitiveness and visible enchantment made it much less partaking for somebody like me who values simple navigation.

One other disadvantage was the time it took for the dashboard to compute and course of evaluation. Even for easy designs, the wait felt unnecessarily lengthy, and I think about this problem could possibly be extra pronounced with bigger, extra complicated tasks. I anticipated the dashboard to ship fast insights, however the delays slowed down my workflow.

I additionally encountered some challenges with the constraint supervisor template creation and reuse. Whereas the constraint system is versatile, creating and reusing templates felt cumbersome. A extra intuitive method right here would considerably enhance the consumer expertise.

Lastly, I seen that assist for importing legacy designs could possibly be extra strong. Though I didn’t extensively take a look at this, importing older designs appeared like a time-consuming course of, and I might see this being a ache level for customers transitioning from different instruments.

What I like about PADS Skilled:

- The flexibility to deal with complicated PCB layouts was a game-changer for me, particularly when engaged on intricate designs requiring exact management. This makes the instrument extremely efficient for detailed tasks.

- The seamless integration with HyperLynx for Sign and Energy Integrity simulations gave me entry to superior evaluation capabilities, enhancing designs with highly effective insights.

What G2 customers like about PADS Skilled:

“It’s extremely useful for backend design and extremely dependable with wonderful accuracy. The consumer interface is supportive {and professional}, making it simple to make use of repeatedly for designing and analyzing PCB fabrication. Integration is easy, and the client assist from Mentor Graphics is excellent. Total, it is easy to implement.”

– PADS Skilled Assessment, Subhadeep P.

What I dislike about PADS Skilled:

- The outdated GUI felt much less partaking and lacked intuitiveness, making it more durable for me to navigate and totally benefit from the consumer expertise in comparison with trendy PCB design instruments.

- Because of its complexity, organising the instrument initially was overwhelming, and a extra streamlined method would have saved me time and diminished frustration in the course of the onboarding course of.

What G2 customers dislike about PADS Skilled:

“One draw back of utilizing PADS Skilled is that it takes a major period of time to course of and compute analyses, even for one thing so simple as the dashboard, which may be fairly irritating.”

– PADS Skilled Assessment, Souvik G.

4. Allegro X PCB Designer

I lately explored Allegro X PCB Designer, and I discovered it distinctive for creating CPU motherboards and dealing with high-density interconnect (HDI) PCB designs.

Its capability to develop compact, space-efficient electronics whereas sustaining superior performance is spectacular. The instrument makes it doable to pack intricate elements into smaller areas, a function that basically stood out to me and felt like a major benefit for contemporary electronics design.

One in every of my favourite options was the error correction system for schematic design. With its three-step course of, it made guaranteeing schematic accuracy really feel intuitive and easy. It flagged errors early, corrected them logically, and validated the outcomes systematically, streamlining the design course of and minimizing potential errors.

I additionally appreciated the pre-analysis and post-analysis capabilities, which allowed me to catch and resolve points each earlier than and after the design section, making the whole workflow extra environment friendly and dependable.

The AI-based part automated the method of arranging parts on the PCB, saving me appreciable time. This automation additionally ensured exact and optimized placements that will usually require meticulous guide changes. It felt just like the instrument was doing the heavy lifting, leaving me free to deal with different elements of the design.

I used to be additionally impressed by Allegro’s versatile workspace, which allowed me to customise the interface, instructions, and workflows to suit my private preferences. This adaptability was an enormous plus, because it made staying organized and productive a lot simpler. Aligning the instrument’s setup with my design habits felt like an effective way to enhance effectivity and luxury.

Nevertheless, the lengthy load occasions, particularly throughout resource-heavy operations, had been irritating. Whether or not it was beginning the appliance, creating library symbols, or working with elements, I seen vital lag. This problem grew to become notably noticeable when dealing with a number of 3D fashions or board mapping, which took for much longer than anticipated and felt like a bottleneck within the workflow.

One other limitation I noticed was the dearth of complete design for manufacturing (DFM) experiences. Whereas the instrument excels at creating PCBs, it doesn’t generate the detailed DFM experiences wanted to make sure a design is prepared for manufacturing. I had to make use of exterior instruments to fill this hole, which added an additional step and a few inconvenience.

Safety issues additionally stood out. The cadence.pcb information aren’t protected properly and may be simply reverse-engineered. For these working with delicate designs, this lack of strong safety might pose vital dangers.

Moreover, the absence of a direct VBScript interface means customers would possibly have to study a brand new scripting language unique to Allegro. Whereas this may be useful for superior customization, the training curve felt unnecessarily steep, particularly for individuals who aren’t acquainted with Allegro’s scripting atmosphere.

What I like about Allegro X PCB Designer:

- Whereas testing Allegro X PCB Designer, I used to be impressed by its capability to create compact and space-efficient designs for CPU motherboards and HDI PCBs. It confirmed actual potential for dealing with trendy, intricate layouts.

- The AI-based automation for arranging PCB elements stood out throughout my trial. It saved me time by optimizing placements and gave me a glimpse of how a lot effort it might eradicate in actual tasks.

What G2 customers like about Allegro X PCB Designer:

“This software program is user-friendly and makes each pre-analysis and post-analysis simple to carry out. It consists of built-in circuit (IC) enter/output buffer info Specification (IBIS) fashions for sign integrity and energy integrity evaluation. The software program affords numerous varieties of evaluation, comparable to electrical evaluation, thermal evaluation, and eye diagram evaluation. It additionally synchronizes simply with seize and gives floor-planning options. Moreover, auto-placement and auto-routing can be found, making the design course of extra environment friendly.”

– Allegro X PCB Designer Assessment, Nikhil Ok.

What I dislike about Allegro X PCB Designer:

- Throughout my testing, I seen vital delays when performing resource-heavy duties like dealing with 3D fashions or board mapping. These lengthy load occasions made the workflow really feel much less environment friendly.

- I discovered the absence of complete DFM experiences limiting. To completely assess my take a look at designs for manufacturing readiness, I needed to discover exterior instruments, which added pointless complexity.

What G2 customers dislike about Allegro X PCB Designer:

“The software program must be backward suitable with older revisions. It requires switching between completely different toolsets, and the whole workflow is not simply built-in. STEP export information do not work properly with SolidWorks, and managing libraries and variants may be troublesome.”

– Allegro X PCB Designer Assessment, Vijay P.

5. Autodesk Fusion

Throughout my testing of Autodesk Fusion, I explored a wide range of options, and it is clear that the software program has so much to supply manufacturing groups.

One facet that stood out to me was the 3D design and modeling instruments. These instruments are extremely highly effective and permit for the creation of each easy components and complicated buildings.

A function I discovered notably useful is manufacturing integration. Fusion permits designs to be taken instantly by way of to manufacturing, which simplifies the method. As an alternative of switching between a number of platforms for design and manufacturing, every little thing is consolidated in a single place. For manufacturing groups, this function is invaluable because it reduces the probabilities of errors and ensures all components of the method are streamlined.

Fusion’s simulation and evaluation instruments enable for simulations like stress exams and movement evaluation, serving to manufacturing groups take a look at designs digitally earlier than transferring to manufacturing. By figuring out potential points, these instruments saved me time, whilst a newbie.

One of the modern options I examined was generative design. This instrument permits me to enter design targets and constraints, and Fusion then generates a number of design choices that meet these standards. For manufacturing groups, this may be extremely helpful for exploring new design prospects and optimizing effectivity, because the software program suggests design options which may not have been thought of in any other case.

Nevertheless, I did encounter a number of challenges throughout testing. Assemblies in Fusion may be troublesome to handle, particularly when coping with bigger designs. Organizing and navigating by way of the completely different components can turn out to be cumbersome, and it may be onerous to shortly find particular elements when changes are wanted.

One other space the place I encountered some issue was with 2D drawings. Whereas Fusion does provide fundamental instruments for creating 2D drawings from 3D fashions, I discovered that the choices obtainable for detailed 2D designs had been restricted. For extra intricate drawings, I needed to export the design to AutoCAD to reap the benefits of extra superior instruments. This lack of flexibility within the 2D instruments could possibly be improved for manufacturing groups that want detailed and complicated 2D representations.

Lastly, I bumped into some points with file conversion when exporting designs. Regardless of Fusion supporting many file codecs, I seen that some intricate particulars and geometries had been misplaced when the designs had been imported into different software program. This could possibly be an issue for manufacturing groups that want exact, detailed designs preserved throughout completely different instruments.

What I like about Autodesk Fusion:

- Throughout my testing, the 3D design and modeling instruments in Fusion had been spectacular. I might simply create easy components and complicated buildings, showcasing the software program’s energy for a spread of design wants.

- Fusion’s manufacturing integration function was an enormous benefit. I appreciated that I might take designs instantly by way of to manufacturing while not having to change between platforms, making the whole course of extra streamlined and fewer error-prone.

What G2 customers about Autodesk Fusion:

“I like utilizing Fusion as an excellent 3D CAD program for creating components or easy meeting designs. The structure and features really feel largely acquainted, and the small variations from different CAD software program I’ve used had been simple to regulate to. Fusion additionally appears designed with collaboration in thoughts, making it simpler to work collectively on designs (though I have never used this function a lot, I can see its worth). One in every of Fusion’s greatest benefits is its value. I had bother convincing administration to pay for 3D CAD software program because of the excessive prices, however Fusion was a lot simpler to justify, costing round 10% of what Inventor or SolidWorks would.”

– Autodesk Fusion Assessment, Justin B.

What I dislike about Autodesk Fusion:

- Throughout my testing, I discovered it difficult to handle assemblies, particularly with bigger designs. Organizing and navigating by way of components grew to become cumbersome, and finding particular elements shortly was troublesome.

- I encountered limitations with 2D drawings, the place Fusion’s fundamental instruments weren’t sufficient for creating detailed 2D representations. I needed to export designs to AutoCAD for extra superior choices, which added an additional step to the method.

What G2 customers dislike about Autodesk Fusion:

“Two elements of Autodesk Fusion 360 that I discover much less favorable are its reliance on an web connection and its CAD file compatibility. Whereas being cloud-based affords vital advantages, options like real-time collaboration and computerized saving may be difficult in areas with restricted connectivity. Moreover, though Fusion 360 helps many file codecs, the conversion course of throughout export is commonly restricted, resulting in the lack of particulars or geometries when importing information into different software program.”

– Autodesk Fusion Assessment, Juan M.

Unlock your design potential with highly effective prototyping software program. Begin constructing and testing your prototypes right this moment to deliver your concepts to life!

6. Altium CircuitMaker

After testing Altium CircuitMaker, I can confidently say that this instrument has so much to supply, notably for these engaged on circuit design. I discovered a number of options that basically stood out, though I additionally encountered a number of challenges alongside the best way.

One of many options I appreciated probably the most was the cloud integration. This allowed me to retailer all designs securely within the cloud, making them accessible from wherever. It was extremely handy, as I did not have to fret about shedding my work or managing cupboard space on my native machine. Moreover, the power to collaborate simply with others is a large plus. Whether or not you are working remotely or on a team-based mission, this cloud function makes it seamless to share and work on designs collectively. The cloud-based nature additionally means I did not need to manually again up my information, which saved a major period of time.

One other function that basically made a distinction was the Fusion 360 plugin. This plugin allowed me to effortlessly bridge the hole between digital and mechanical designs. I might work on my circuit design in CircuitMaker after which seamlessly transfer to Fusion 360 to tweak the mechanical elements or vice versa. This fluid integration between the 2 platforms saved me hours of transforming and resolving alignment points, guaranteeing that my digital and mechanical designs aligned completely.

The 3D know-how for visualizing schematics was additionally a game-changer. Seeing designs in 3D helped me perceive how the circuits would work together as soon as they had been bodily constructed. It offered me with a a lot clearer image than conventional 2D views, and I used to be in a position to spot potential errors early on which may have been missed in a 2D atmosphere.

I additionally actually appreciated the power to simply assign properties to elements. Including feedback or particular attributes to components helped me keep organized and hold observe of modifications all through the design course of. It was notably helpful for leaving reminders to myself or others about sure design choices or particular components, guaranteeing nothing was missed.

The library that comes pre-loaded with Altium CircuitMaker is intensive and a real-time-saver. It consists of a variety of symbols, footprints, and 3D fashions, so I didn’t need to go attempting to find components. I might entry not solely the components themselves but additionally vital particulars like costing, stock info, and even distributor solutions. This made the designal course of a lot simpler, particularly once I didn’t have a pre-defined components checklist. I might shortly pull up related elements and begin designing with out losing time on analysis or stock checks.

Nevertheless, there have been some challenges. Whereas the simulator mannequin works properly for fundamental simulations, I discovered that the accuracy wasn’t all the time dependable for extra complicated circuits. The simulations typically didn’t precisely replicate real-world habits, which made me query whether or not a number of the designs would perform as anticipated as soon as constructed. This could possibly be problematic for extra intricate designs the place exact habits is crucial.

One other problem I confronted was the shortcoming to save lots of my tasks offline. Because the mission file needed to be saved within the cloud, I couldn’t work with out an web connection. This was notably inconvenient once I was in an space with poor connectivity or once I simply needed the flexibleness to work offline. Whereas the cloud integration is nice total, I might have most popular the choice to save lots of tasks domestically for added flexibility and safety.

Moreover, I discovered the heavy reliance on neighborhood sharing to be a little bit of a disadvantage. Whereas the concept of sharing work with a big consumer base may be interesting to some, I personally favor extra management over my tasks. The community-driven facet felt a bit limiting, and I might have favored extra independence in how my work is shared or stored non-public. For individuals who take pleasure in working independently, this could possibly be a deal-breaker.

Lastly, as a Linux and MacOS consumer, I discovered the expertise lower than very best. Since CircuitMaker is primarily designed for Home windows, I hadvert to arrange a digital machine to run the software program. Whereas it labored high quality throughout the digital machine, it added an additional layer of complexity to the setup. It wasn’t as seamless as utilizing a local software, and I might see how this could possibly be irritating for customers exterior of the Home windows ecosystem.

What I like about Altium CircuitMaker:

- I appreciated the cloud integration, which allowed me to retailer designs securely and entry them from wherever. It made collaboration simple, and I didn’t have to fret about backing up information manually.

- The Fusion 360 plugin was extremely helpful. It allowed me to seamlessly transition between digital and mechanical design, saving me plenty of time by avoiding alignment points between the 2 platforms.

What G2 customers like about Altium CircuitMaker:

“CircuitMaker is a superb instrument for designing and working electrical circuits. Its intuitive interface lets you shortly draw, modify, and mix layouts with ease. It is a exact instrument that makes it easy to grasp the theoretical elements {of electrical} circuits. With this system’s libraries, you possibly can create spectacular tasks, and discovering a component is made simple by way of a nested construction inside subfamilies. This instrument consists of all the mandatory options for use professionally in your organization or group.”

– Altium CircuitMaker Assessment, James Michael W.

What I dislike about Altium CircuitMaker:

- I encountered points with simulation accuracy for complicated circuits. The simulator typically didn’t precisely replicate real-world habits, which raised issues in regards to the reliability of designs for extra intricate tasks.

- The shortcoming to save lots of tasks offline was a serious inconvenience. Because the information needed to be saved within the cloud, I couldn’t work with out an web connection, which restricted my flexibility in sure conditions.

What G2 customers dislike about Altium CircuitMaker:

“CircuitMaker enforces cloud saving and permits solely two non-public tasks, which may be limiting. The neighborhood part library is unmoderated, containing many unusable footprints (although it is beneficial to create your individual, because the part wizard makes it simple). The software program may be considerably unstable, so saving steadily is vital. Moreover, the keyboard shortcuts differ from these in Altium Designer, which can take a while to regulate to.”

– Altium CircuitMaker Assessment, Alberto V.

7. Autodesk EAGLE

One function of Autodesk EAGLE that stood out to me nearly instantly was the consumer language applications (ULP), the built-in programming language. It helped me save time by automating repetitive processes, which might be useful when engaged on a number of designs or making frequent changes. I might create customized scripts tailor-made to my wants, giving me larger management over the workflow. For manufacturing groups seeking to velocity up manufacturing, this function generally is a real-time-saver.

The autoroute perform is one other instrument that simplifies the design course of. In a producing context, the place time is vital, the power to shortly route paths with minimal guide effort was invaluable. It allowed me to generate fast prototypes and focus extra on refining the core design reasonably than coping with routing points.

The instrument labored easily for schematic seize, which is essential in manufacturing for guaranteeing accuracy. It helped me spot potential points early, lowering the probability of errors throughout manufacturing.

On the library administration aspect, Autodesk EAGLE impressed me with its intensive collection of pre-loaded CAD packages. This meant much less time spent looking for elements, permitting for quicker meeting and prototyping in manufacturing.

One draw back I encountered was with the 3D visualizer. Whereas useful, it didn’t provide the extent of accuracy I anticipated when visualizing how a PCB would look as soon as produced. In manufacturing, this stage of precision is crucial to make sure every little thing matches collectively accurately, and EAGLE’s 3D instrument didn’t fairly meet these expectations.

I additionally had points with the web itemizing function, particularly when working with complicated energy PCBs. It didn’t all the time perform as anticipated, which led to delays and potential errors within the design section. Dependable web listings are important for guaranteeing correct electrical connections within the closing product.

One other limitation was the restriction within the downloaded model of EAGLE, which limits designs to simply two layers. This turns into a problem when working with extra complicated, multi-layer boards. For manufacturing groups engaged on high-density designs, this restriction could cause delays, forcing groups to discover various options or go for dearer variations of the software program.

Lastly, I really feel that routing intelligence could possibly be improved. Presently, EAGLE makes use of normal routing paths, however integrating AI-based routing algorithms would considerably enhance effectivity. This might lead to extra compact, optimized designs, velocity up manufacturing occasions, and reduce routing-related errors.

What I like about Autodesk EAGLE:

- The consumer language applications (ULP) function stood out to me as a result of it allowed me to automate repetitive processes. Creating customized scripts saved me time and supplied larger management, particularly helpful for groups engaged on a number of designs.

- The autoroute perform was an actual time-saver for me. It shortly generated routing paths with minimal effort, enabling me to create prototypes quicker and focus extra on refining the core design as an alternative of coping with routing points.

What G2 customers like about Autodesk EAGLE:

“The CoA template was custom-made to fulfill our wants, together with all important consumer and pattern particulars, together with a desk displaying analytes and their noticed values. Every desk cell was designed to seize values primarily based on particular take a look at sorts. The CloudLIMS group collaborated carefully with us to make sure the template matched our expectations. They automated calculations and utilized built-in logic and complicated algorithms to make this occur.”

– Autodesk EAGLE Assessment, Ronel C.

What I dislike about Autodesk EAGLE:

- I discovered the 3D visualizer to be a bit missing in accuracy. It didn’t present the extent of precision I wanted to visualise how the PCB would look as soon as produced, which might result in potential fitment points within the manufacturing section.

- I encountered points with the web itemizing function, notably when working with complicated energy PCBs. It didn’t all the time work as anticipated, which brought about delays and will have led to errors in guaranteeing correct electrical connections for the ultimate product.

What G2 customers dislike about Autodesk EAGLE:

“The system’s session timeout is sort of restrictive, because the platform prompts session expiration after a brief interval. It will be useful if there have been an choice to increase the session period, giving customers extra flexibility to finish duties with out the priority of shedding their progress.”

– Autodesk EAGLE Assessment, Aryan Ok.

Finest PCB design software program: steadily requested questions (FAQs)

Q. How do I design a PCB?

To design a PCB, begin by making a schematic diagram that outlines the circuit elements and their connections. Then, use PCB design software program to transform the schematic right into a PCB structure, inserting elements and routing the traces. After finishing the structure, generate the mandatory information for manufacturing, comparable to Gerber information, and guarantee design guidelines and electrical constraints are met.

Q. Can I design a PCB on cellular?

Sure, some PCB design apps can be found for cellular units, although they have an inclination to have fewer options in comparison with desktop variations. These cellular apps are appropriate for fundamental design duties and easy tasks, however for extra complicated designs that require superior performance, desktop software program is beneficial on account of its larger precision and complete toolsets

Q. How do I study PCB design?

You may study PCB design by way of on-line programs, tutorials, and books that cowl electronics and circuit design. Start by understanding fundamental ideas like circuit schematics and part placement, after which apply utilizing free PCB design software program. Begin with easy circuits to construct your abilities earlier than progressing to extra complicated tasks. Partaking with on-line boards or communities can present precious suggestions and steering, serving to you achieve confidence earlier than utilizing superior design instruments.

Q. How do I select the best PCB structure design for my mission?

Selecting the best PCB structure design depends upon elements just like the mission’s measurement, complexity, and required performance. Contemplate the variety of layers, the kind of elements used, thermal administration, and sign integrity. For prime-speed circuits, pay particular consideration to routing and grounding. Moreover, make sure the structure meets any industry-specific necessities (e.g., automotive or medical requirements).

Q. Which is the very best free PCB design software program?

Most high-quality PCB design software program instruments are paid, however many provide free trials that will help you get began. Altium Designer, for instance, is broadly considered the most effective instruments within the {industry}, providing highly effective options for complicated designs. Its free trial generally is a good place to begin. Discover extra free PCB design software program that provides fundamental options, which may be helpful for easier tasks or rookies.

Preserve issues grounded

Selecting the best PCB design software program generally is a game-changer on your tasks. When evaluating these instruments, it’s important to think about elements like usability, efficiency, and options that finest align along with your particular wants—whether or not that’s dealing with complicated designs, bettering sign integrity, or guaranteeing clean collaboration.

Based mostly on my testing and consumer suggestions, I’ve outlined the highest instruments that supply the very best mixture of effectivity, flexibility, and energy. One of the best instrument is the one which works for you and helps you deliver your PCB designs to life with none hiccups.

Don’t be afraid to dive in, experiment with completely different choices, and see what clicks. Keep in mind, even probably the most refined software program can’t assist when you don’t press the best buttons (except you’ve received a “design wizard” in your group, by which case, please share their contact data with me).

Cut back errors through the use of simulation and take a look at suites earlier than transferring your PCB design to manufacturing.